Quick contact

Ing. Martin Zach

+420 731 495 916

martin.zach@kovo-zach.cz

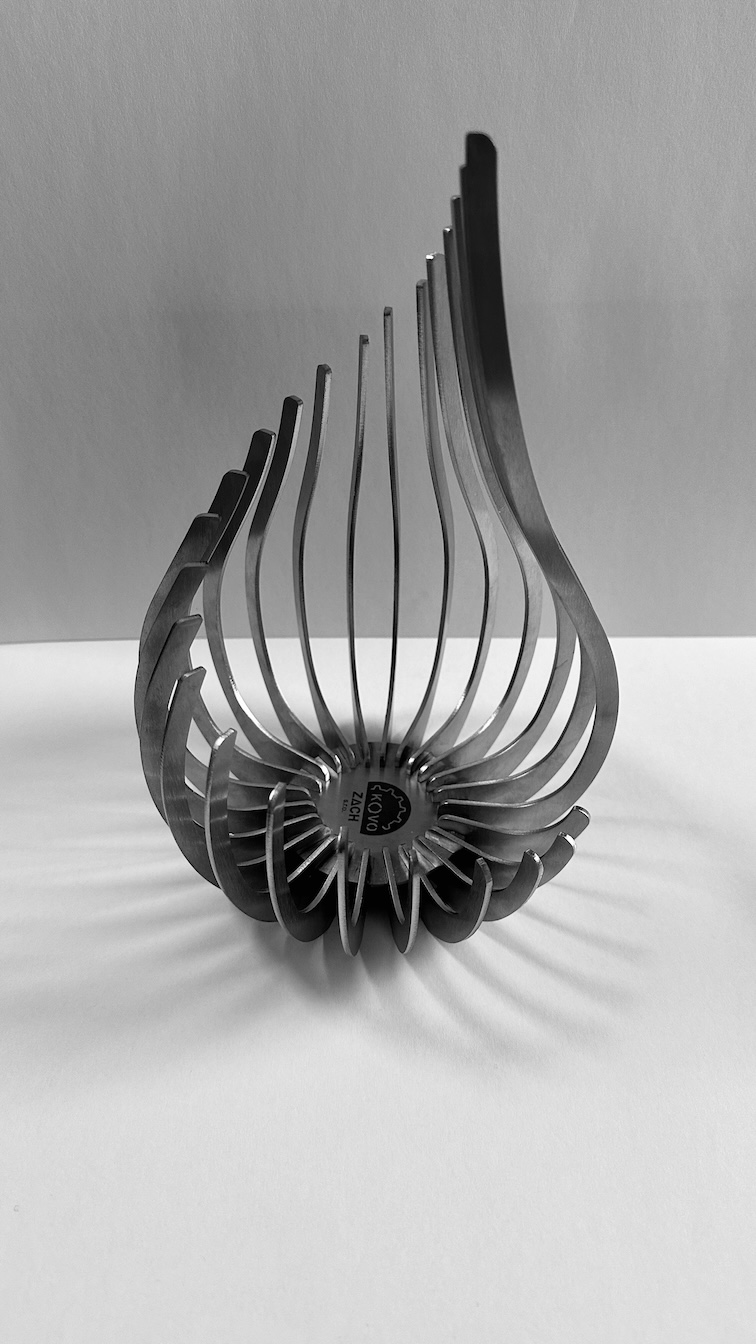

Laser cutting and engraving

We divide sheets, tubes, pipes, rods and strips. We keep materials of various standards and thicknesses in stock.

Fiber laser

We burn parts of varios shapes on a CNC fiber laser with a power of 3 kW. Compared to plasma or water jet the cut is cleaner and more precise. We burn material from a thickness of 0.1 mm, namely steel (up to 20 mm), stainless steel (up to 10 mm), aluminium alloy (A1Mg3, up to 5 mm) and zinc-coated steel (max. thickness 4 mm). The maximum size of the sheet metal is 3000x1500 mm and an usual cut allowance 0,1 mm.

For each stock item, we record a material certificate from the supplier, which we are then able to document for each article of the order at the request of the customer, thanks to the registration during production in the ERP system developed by us.

We deliver materials of atypical standards only on the condition that at least the entire format is taken.

Jäkl constructions are divided into band saws. However, we can also burn 2D shapes into profiles.

Profit from the possibility of sending the drawing documentation via electronic mail (DWG, DXF, STP, PDF formats).

- Making of non-binding offer

- Distinctive approach to all orders

- Short delivery time

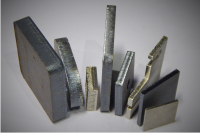

Deburring & tumbling

Small parts are placed in a tumbling machine, where we apply a suitable abrasive based on the material and the size of the part. Thanks to the rotation of the machine, the abrasive is mixed with the parts, and thus the burrs are ground and the edges are partially chamfered.

Larger parts up to a maximum width of 600mm are placed in a continuous deburring machine, which is equipped with an input sanding belt for removing burrs, a carousel for chamfering edges (a multi-directional processing system using four rotating brushes) and a final sanding belt to ensure even sanding.

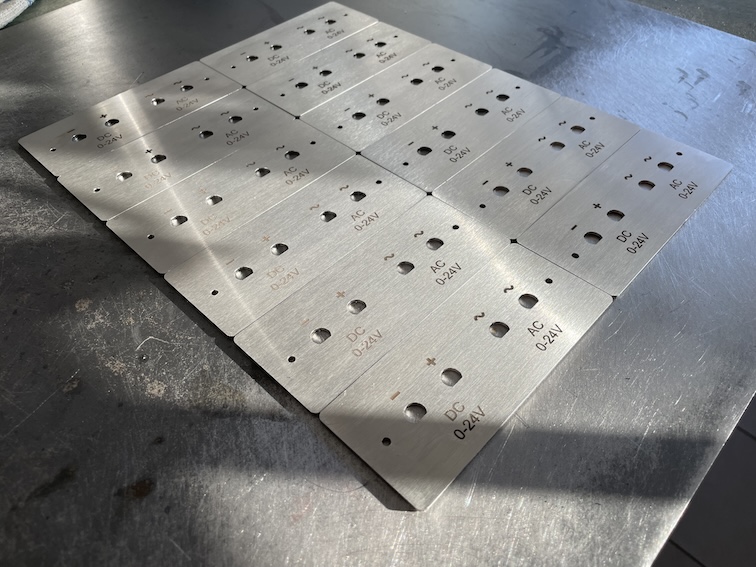

Laser engraving

We ensure laser engraving with high precision. By using of laser we engrave and produce instrument, production labels, corporate gifts and promotional items.

Possibilities of marking: metal, plastic, aluminium, precious metal, marking of bearings, spectacle frames, keyboards, meassure tools, plastic items, electronic components, different type of cabels, medical equipment, aluminium covers ford medicines, ets.

Advantages of laser marking: indelibility, permanence, precision, detailed processing, resistant, contactless method, originality.

- Suitable formats - vector or bitmap graphic

- Making of QR, DMA and BAR codes

- Permanent identification

Drilling, threading and deepening

We have a number of drilling and countersinking tools. We then perform all operations on a stand drill.